Malaysia’s semiconductor industry is entering a new growth cycle, powered by the National Semiconductor Strategy (NSS), ongoing global chip demand, and a pipeline of new investments. For B2B manufacturers and suppliers in this ecosystem, the right ERP is no longer just a back-office system - It is the backbone for yield, traceability, compliance, and profitable growth.

In this article, we are going to show you the big view of Malaysia’s semiconductor manufacturing landscape and the critical role of ERP in scale growth for this industry.

Overview of Malaysia’s Semiconductor Landscape and Digital Gaps

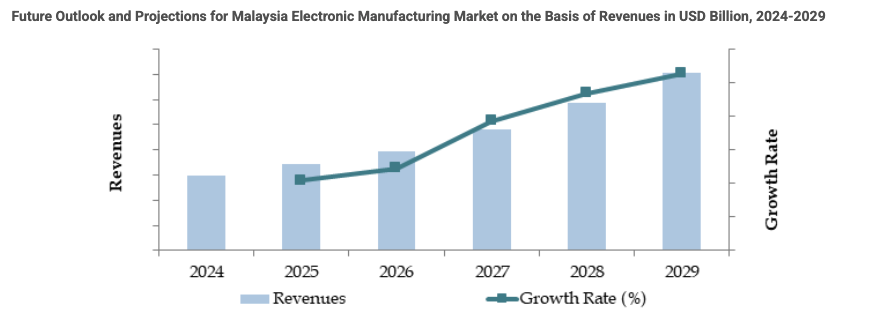

(Source: Trade Data Research)

Malaysia has long been a strategic player in the global semiconductor value chain. From assembly, testing, and packaging (OSAT) to equipment, materials, and increasingly higher-value manufacturing activities, the country continues to attract multinational investments while nurturing a growing ecosystem of local suppliers.

This expansion increases complexity across materials, processes, and regulatory requirements, exposing the limitations of spreadsheets, legacy on‑premise systems, and disconnected point solutions that many plants still rely on.

For local OSATs, substrate makers, precision engineering firms and equipment suppliers, typical pain points include poor data visibility, manual production planning, weak traceability, and difficulty integrating with manufacturing execution system (MES), automation, and customer systems. Larger global original equipment manufacturers (OEMs) and integrated device manufacturers (IDMs) demand higher transparency and faster response times.

As a result, many semiconductor manufacturers in Malaysia are facing a common challenge:

Their internal systems are no longer able to support operational complexity. ERP for semiconductor industry in Malaysia becomes a strategic enabler rather than just an IT project.

MES vs ERP: Understanding the Difference

Aspect | ERP | MES |

Focus | Business & planning | Shop-floor execution |

Time horizon | Days to months | Real-time |

Users | Management, finance, supply chain, inventory,... | Operators, Supervisors |

Scope | Enterprise-wide | Production floor |

Benefits | Cost visibility, Planning accuracy, Compliance and reporting. | Execution accuracy, Real-time control, Process discipline. |

Core functions | - Finance & Accounting - Procurement & Supplier Management - Inventory Management - Production Planning (MRP) - Quality Management - Reporting & Analytics | - Real-time tracking of lots, batches, and serial numbers - Machine status and performance monitoring - Operator instructions and work orders - Yield, scrap, and defect tracking - Process enforcement and genealogy. |

ERP and MES are not competing systems. They are complementary.

What Makes Semiconductor ERP Different - Key Requirements

An effective ERP for semiconductor industry in Malaysia should support:

- Advanced production planning and scheduling that can integrate with MES and capture re‑entrant routing, multiple work centres, and constraints like cleanroom capacity and tool qualification.

- Lot/batch - and in some cases unit - level traceability, enabling full genealogy from wafer and substrate through assembly, test, and final device shipment, supporting RMAs and customer audits.

- Quality management including SPC, non‑conformance handling, CAPA, and audit trails aligned with ISO, IATF, and customer-specific standards common in global electronics supply chains.

- Engineering change management with structured approvals and integration to PLM or design tools is crucial when recipes, masks, or test programs change frequently.

- Global trade, tax, and multi-entity finance capabilities for Malaysian operations that are part of larger regional or global corporate structures.

How ERP Supports Semiconductor Growth in Malaysia

ERP for semiconductor industry in Malaysia directly links to measurable outcomes in efficiency, quality, and customer satisfaction. Below are four key value areas that resonate strongly with B2B C-Level needs:

Improving Production Efficiency and Yield

ERP integrated with MES and equipment data provides end‑to‑end visibility of WIP, bottlenecks, and machine utilisation, allowing planners and supervisors to rebalance loads and reduce unplanned downtime quickly. This is especially critical for high‑mix OSAT lines and precision tooling or component suppliers serving multiple semiconductor customers with tight lead times and frequent changeovers.

By standardising routings, capturing accurate cycle times, and closing the loop between planned versus actual performance, ERP helps identify chronic yield issues and process drifts far earlier than spreadsheet-based approaches. Over time, this supports continuous improvement programs and makes it easier to justify capital expenditures for new tools or expansions to corporate headquarters using trusted data.

Strengthening Traceability and Compliance

Global customers increasingly expect Malaysian plants to provide full genealogy for every lot and, where relevant, every device - from initial wafer lot through assembly, test, and packing. A semiconductor‑ready ERP records materials, process steps, test results, and deviations against each lot, so QA and engineering teams can quickly trace any field failure back to specific batches, equipment, or process windows.

This level of traceability significantly reduces the time and cost of managing audits, RMAs and customer quality escalations, while also protecting brand reputation and long‑term contracts. As Malaysia pushes deeper into higher‑value segments under NSS and becomes more visible in global supply chains, being able to demonstrate robust digital traceability becomes a differentiator in winning and retaining major B2B customers.

Building Resilient Supply Chains in a Volatile Market

The global semiconductor market remains cyclical, with rapid swings in demand and persistent risks around materials, logistics, and geopolitics. ERP gives Malaysian manufacturers an integrated view of demand forecasts, supplier commitments, inventory positions, and capacity, enabling more informed decisions on safety stocks, alternative sourcing and production prioritisation.

For companies dealing with wafers, substrates, specialty chemicals, gases, and critical tooling, the ability to simulate scenarios and understand the impact of delays or shortages is crucial to meeting contractual obligations. This level of supply chain visibility also supports collaborative planning with key customers and suppliers, positioning Malaysian plants as reliable long‑term partners in a regionally diversified supply chain strategy.

Enabling Data‑driven Decisions for Plant and The Headquarters

Modern ERP platforms consolidate operational, financial, and quality data into dashboards that speak both the language of the shop floor and the boardroom. Plant directors can track metrics such as OEE, yield by product or line, cost per unit, and on‑time delivery, while finance and corporate teams can evaluate profitability by customer, product family, or site.

For multinational corporations investing in Malaysia as a regional hub under the NSS, having standardised ERP data and processes makes it much easier to compare performance across plants, allocate capital, and integrate new acquisitions or expansions. This also lays the foundation for AI and advanced analytics initiatives that the government is promoting alongside semiconductor growth.

Choosing The Right ERP for Semiconductor Industry in Malaysia

When evaluating ERP for semiconductor industry in Malaysia, B2B decision‑makers should consider:

- Industry fit and manufacturing depth: availability of semiconductor‑relevant features and proven deployments in semiconductor or high‑precision manufacturing.

- Local compliance readiness: support for Malaysian SST, LHDN requirements, e‑invoicing roadmap, banking integrations, and HR/payroll where needed.

- Integration and automation: ability to connect with MES, PLM, test systems, automation, and customer or supplier portals without excessive custom development.

- Partner capability: presence of local implementation teams with strong manufacturing domain expertise and experience in validation and audits, not just basic accounting rollouts.

Many manufacturers in Malaysia are transitioning from legacy On-Premise systems and highly customized solutions to Cloud or hybrid ERP, Modular, and scalable platforms.

For industries like manufacturing these limitations as below are considered as a loss of productivity, higher operating costs, and weaker competitiveness in the market:

- High costs: On-premise ERP requires heavy investment in hardware, licenses, and IT maintenance.

- Limited scalability: Expanding operations means buying more infrastructure.

- Slow adaptability: Hard to integrate with new technologies.

- Data silos: Older ERP systems don’t integrate well, limiting real-time insights.

For B2B players evaluating ERP for semiconductor industry in Malaysia, it helps to categorise solutions into a few practical tiers that match different business sizes, operational complexity profiles and growth stages.

- Tier-1: Multinational semiconductor companies operating in Malaysia typically rely on enterprise-grade global ERP platforms such as SAP S/4HANA, Oracle ERP Cloud, or Microsoft Dynamics 365, often deployed using global templates with local statutory and operational localization to meet Malaysian compliance requirements.

These systems provide deep capabilities across finance, supply chain, manufacturing planning, quality management, and consolidation, making them suitable for high-volume, multi-plant, and HQ-driven environments.

- Tier-2: Mid-sized and fast-growing semiconductor manufacturers and suppliers increasingly adopt cloud or hybrid ERP solutions that are modular and scalable, allowing them to start with core modules such as finance, inventory, and procurement before expanding into production planning, quality, and analytics as operational maturity increases.

Within this segment, Odoo ERP has emerged as a popular choice in Malaysia due to its open-source architecture, flexible modular design, and cost-effective implementation, particularly for companies seeking strong manufacturing, inventory, and traceability capabilities without the complexity or cost of traditional enterprise ERP systems.

- Tier-3: Local SMEs within the semiconductor supply chain often begin their ERP journey by migrating from standalone accounting software or spreadsheet-based operations to lighter ERP platforms such as Odoo, which provide improved inventory control, lot tracking, purchasing visibility, and integrated reporting while remaining scalable for future growth.

In addition, many semiconductor manufacturers operate in hybrid environments, integrating ERP with specialized MES and shop-floor systems to maintain strict production control while using ERP as the central planning, financial, and compliance backbone.

Regardless of ERP systems, selecting the right ERP implementation partner in Malaysia is as critical as choosing the software itself; manufacturers should prioritize partners with proven manufacturing experience, strong knowledge of local regulatory and statutory requirements, and the ability to balance global ERP standards with local operational practices. A capable ERP partner should extend beyond technical implementation to provide process alignment, change management, user training, and ongoing support, ensuring the ERP system delivers sustained business value rather than becoming a fragmented IT tool.

Conclusion

As Malaysia continues to strengthen its position in the global semiconductor supply chain, manufacturers must operate with greater transparency, control, and agility. ERP systems - particularly when well integrated with MES - provide the digital foundation needed to manage complexity, ensure compliance, and support sustainable growth. Choosing the right ERP platform is only the first step; success ultimately depends on working with an experienced implementation partner who understands both semiconductor operations and the local business context.

To evaluate ERP for semiconductor industry in Malaysia aligned with your NSS and export growth plans, contact A1 Consulting team for further or explore our resources hub for more detailed guides, ERP information and success stories from our Malaysia customers.

Sally N.

BDM - Partner and Alliance

With over 7 years of experience in ERP advisory, Sally has worked closely with SMEs across Malaysia to streamline operations and drive digital transformation. Her deep understanding of business processes and hands-on approach have made her a trusted advisor to many growing companies. Through this blog post, Sally aims to share practical insights and real-world lessons drawn from her implementation experience, offering guidance to businesses navigating their own ERP journey.