Building a product from concept to completion demands absolute precision. For manufacturers, Bill of Materials (BOM) management software is the backbone of the manufacturing process. Managing it without the right tools often leads to costly mistakes - this is what our experts with many years of experience confirm. BOM management software acts as the compass, guiding operations towards seamless execution and absolute precision until the product is launched.

Typically, you use manual tracking methods, such as spreadsheets, which are definitely outdated in 2025. They are extremely lacking in the depth and reliability required for complex production cycles. In parallel with the rapid development of technology, Malaysian businesses need to quickly seek and adapt to intelligent BOM management software solutions that provide control and transparency even in the face of complexity in navigation.

With the deep experience of implementing in the manufacturing industry in Malaysia of leading experts, we have written this article to provide you with the top 10 popular and reputable BOM management software in Malaysia, and at the same time equip you with deep insights to quickly integrate and have for yourself the ideal choice to master the manufacturing process.

Speed and quality are two factors that help you stay one step ahead of your competitors, and BOM management software is one of the pioneering conditions to make this journey more certain than ever.

Why is BOM Management Software Crucial for Your Malaysia Business?

Manufacturing thrives on precision. BOM management software turns chaos throughout the workflow into structured control and near-perfect accuracy through automation.

Streamlines material planning

Efficient material planning is the foundation of a holistic and comprehensive manufacturing process. BOM management software structures every single component into a centralized system, eliminating oversights. Manufacturers in Malaysia, throughout their complex supply chain processes, can accurately identify material shortages before they become critical and disrupt operations.

For example, Tadano, a global manufacturer, has radically improved its pre-production process by implementing separate bills of materials on their BOM management software. This has resulted in more efficient preparation, development, and production (according to Cenit).

Reduces production errors

Errors in production cost more than money-they damage reputations. BOM management software reduces errors by aligning all available materials, processes, and costs to exact specifications. Malaysian businesses in fast-moving sectors, like automotive, experience fewer defects when processes rely on accurate data.

The BOM management tools act as a safety net, maintaining product integrity at scale.

Supports compliance and quality standards

Compliance is non-negotiable in a competitive market like Malaysia. BOM management software plays a role in tracking material sources and certification, safeguarding quality assurance. This is especially important in industries that require tight and strict control over product output standards, such as the food & beverage industry.

The assurance in the way BOM management tools operate prevents legal risks for manufacturers and thoroughly strengthens customer trust.

Cuts hidden costs

Costs that hide beneath the surface often cause the greatest damage. BOM management software clearly identifies these blind spots, such as unused inventory, high material consumption, or outdated stock.

With close and accurate cost tracking, these software are powerful tools for businesses to gain visibility into every expense, thereby identifying areas that need tightening. A real-life example? A Malaysian electronics company discovered that overstocking just one type of capacitor was causing their annual losses to exceed RM100,000. Their solution: BOM management software - successfully adjusting purchasing volumes, cutting waste, and restoring profitability.

Fosters team synergy

BOM management software creates a central workspace where designers, procurement officers, and production managers access real-time data. This eliminates version conflicts or mismatched processes.

These tools integrate operations, simplifying the work of both managers and employees from different departments, thereby aligning schedules and aligning all resource-related needs. This cohesion not only prevents costly mistakes but also strengthens interdepartmental trust, fostering long-term operational harmony.

Take the case of a Malaysian furniture manufacturer with multiple branches across Penang and Selangor. Without the powerful support of BOM management software, how chaotic and difficult would things be?

You should also read this article: Top 10 Inventory System Malaysia for Streamlined Operation: Explore Now!

Top 10 BOM Management Software You Should Consider: Enhance The Entire Process

Odoo

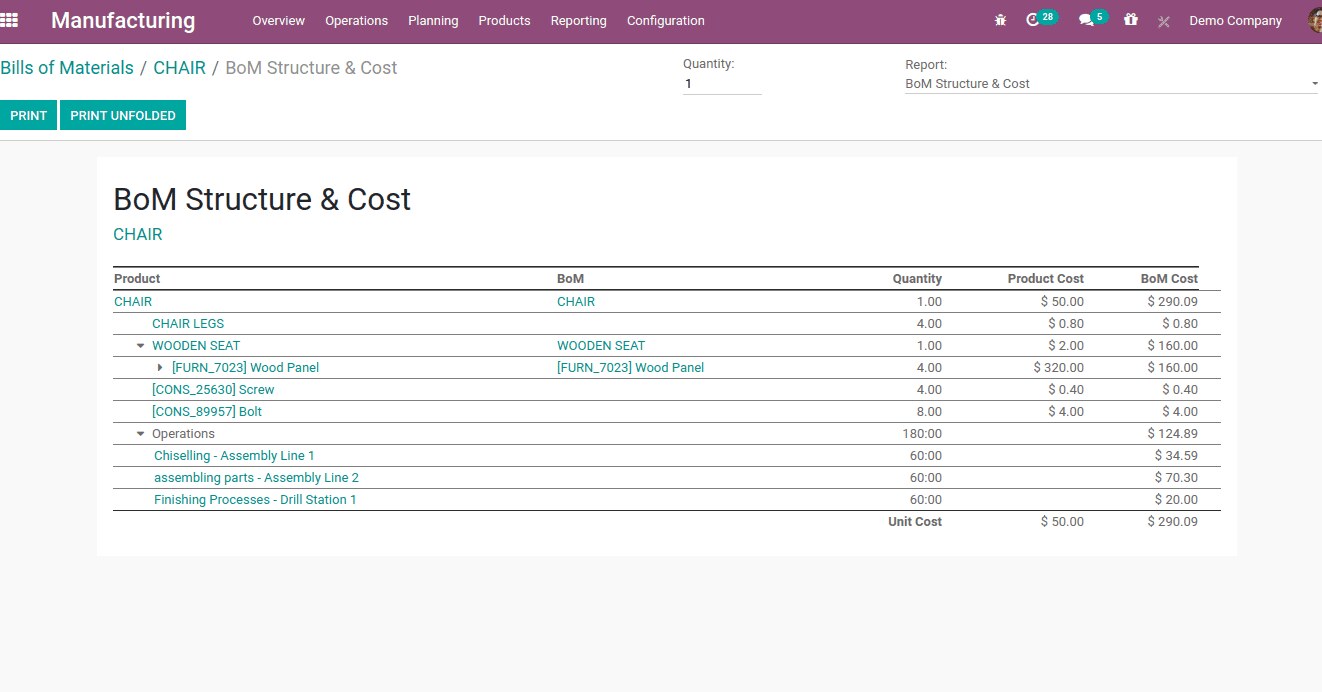

Odoo BOM management software is a prominent solution in the Malaysian market that every manufacturer must take a clear look at. Its modular system offers customizable features to simplify the entire material and manufacturing management process.

This system is scalable, adaptable to any business regardless of size or complexity. Integrating Odoo as a BOM management software creates a manufacturing system that works smoothly, uniformly, and extremely efficiently.

Key features

- Dynamic BOM structure: Easily customizes multi-level BOMs for complex manufacturing processes.

- Real-time inventory tracking: Accesses live data on the availability and consumption of all raw materials.

- Production cost analysis: Tracks costs at every stage of manufacturing with absolute accuracy.

- Seamless integration: Combines BOM management with other key Odoo modules such as Inventory, Sales, and Odoo Manufacturing.

- Version control: Tracks BOM revision versions to avoid outdated or conflicting configurations.

Pros

- User-friendly modular interface

- Comprehensive multi-level BOM management

- Integration with financial and inventory systems

- Automated production scheduling

Cons

- Limited customization without additional development

- Steeper learning curve for non-tech users

Best for

Odoo BOM management software is an ideal choice for medium and large manufacturing businesses in Malaysia. It is suitable for industries such as electronics, automotive, and machinery with complex assembly processes-which need support for managing operations at multiple locations or accurate cost tracking, resource planning.

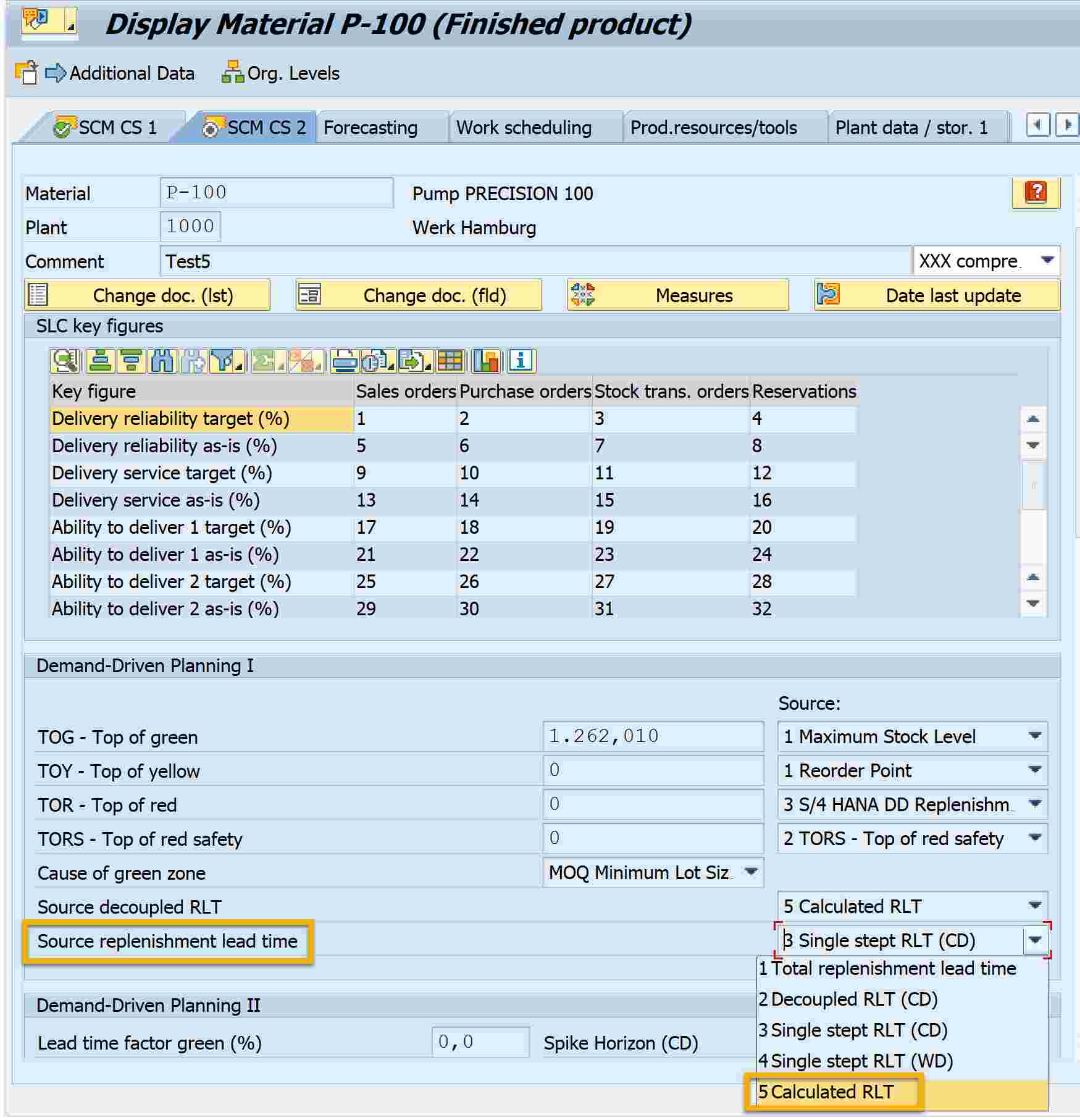

SAP

SAP is the cornerstone solution as an advanced BOM management software in enterprise-level manufacturing. Deep integration with other modules in the SAP ecosystem creates a seamless and efficient set of operations. SAP delivers unmatched accuracy and operational quality across the entire material handling, procurement, and manufacturing process.

Key features

- Centralized material master data: Consolidates all material and vendor information into a single, secure database.

- Advanced procurement management: Processes purchase orders and vendor negotiations with unmatched precision.

- Invoice verification: Aligns invoices with purchase orders and deliveries to maintain financial integrity.

- Comprehensive inventory oversight: Tracks inventory movements, balances, and valuations in real time.

- Custom reporting and analytics: Provides actionable insights through detailed procurement and material reports.

Pros

- Industry-leading integration across ERP modules

- Precision-focused material master data handling

- Robust analytics and reporting capabilities

- Comprehensive inventory and procurement controls

Cons

- Rigid structure unsuitable for smaller, agile businesses

- Complex implementation with extensive customizations

Best for

As an excellent BOM management software, SAP is ideal for large Malaysian businesses with complex manufacturing and supply chain operations. It serves industries such as oil and gas, heavy machinery, and automotive manufacturing. Note: your business needs to have enough resources to manage its complexity.

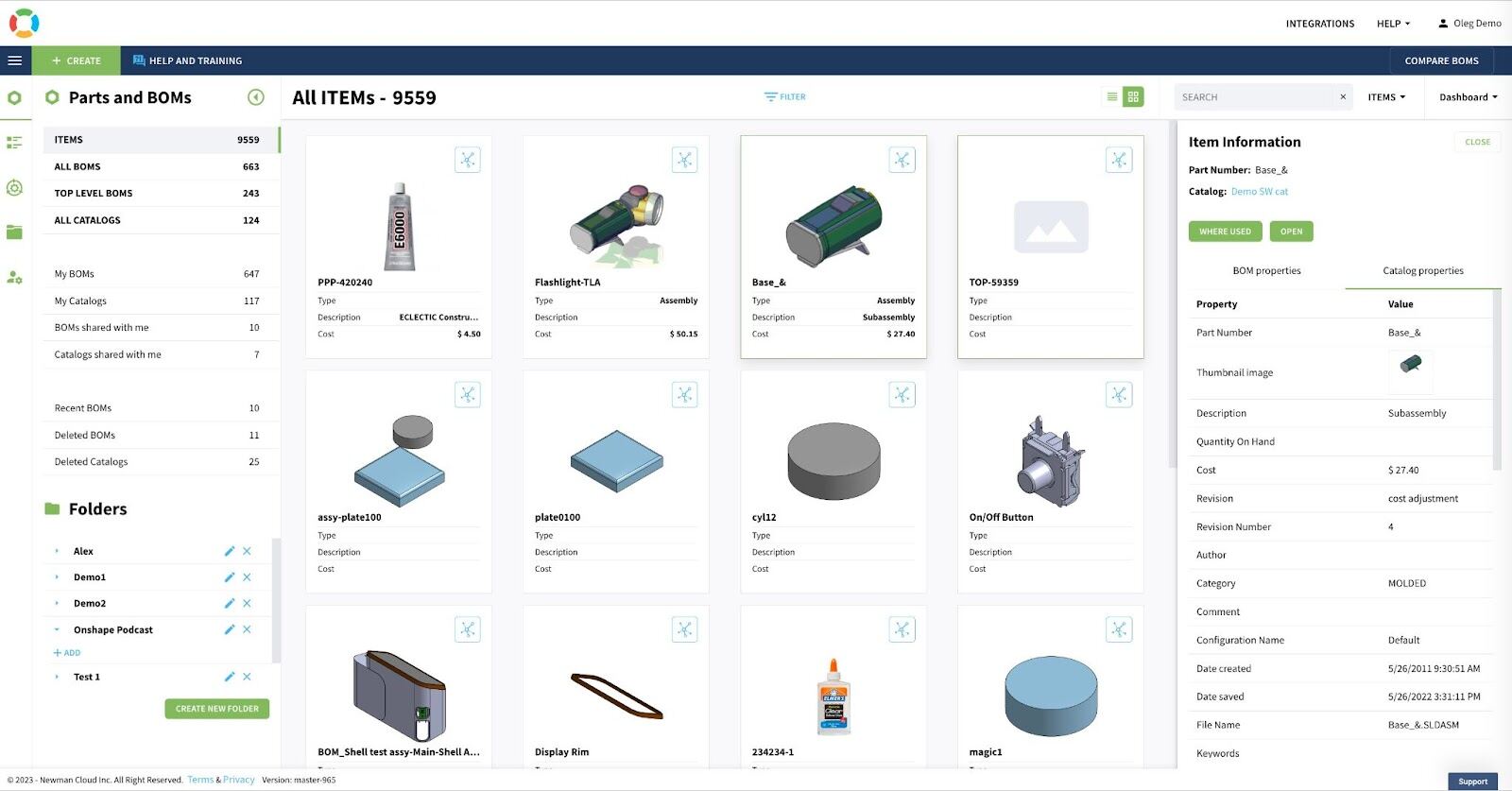

OpenBOM

OpenBOM is a cloud-based BOM management software designed specifically for real-time collaboration. It simplifies the management of product data, supply chain, and workflows in a centralized platform.

OpenBOM’s user-friendly interface is a strong point and is also a key factor for businesses that are gradually moving from using spreadsheets to a structured system without feeling overwhelmed. OpenBOM stands out for its scalability and strong adaptability in Malaysia’s dynamic manufacturing environment.

Key features

- Real-time collaboration: Allows multiple users to edit and share BOM data simultaneously.

- Centralized inventory control: Synchronizes inventory updates across all BOMs with precision.

- CAD (Computer-Aided Design) integration: Seamlessly connects with leading CAD tools to streamline workflows.

- Vendor and purchase order management: Efficiently track procurement activities and vendor data.

- Revision control system: Maintain historical BOM versions for accurate tracking of changes.

Pros

- Intuitive interface for simplified navigation

- Flexible integration with CAD and ERP tools

- Cost-effective subscription plans with scalability

- Centralized data storage on a secure cloud platform

Cons

- Limited hosting options with no dedicated server support

- Basic email-only customer service

- Simplified change management unsuitable for large enterprises

Best for

OpenBOM is ideal for Malaysian SMEs in the manufacturing sector, especially consumer goods, electronics, or machinery. Its affordable price and seamless CAD integration make it a powerful choice for engineering teams.

Kohezion

Kohezion is a BOM management software designed to adapt to diverse business requirements. With Kohezion, the rigidity of traditional BOMs management systems is completely eliminated, and the user experience is also put at the center. Its intuitive setup reduces complexity while still thoroughly promoting efficiency and scalability. Kohezion makes BOM management a seamless and agile experience.

Key features

- Customizable database platform: Tailors applications to specific needs without programming expertise.

- Real-time team collaboration: Maintains synchronized updates and transparency across teams.

- Task and inventory management: Tracks inventory levels and organizes tasks with centralized precision.

- Scalable cloud-based system: Scales as your business grows while ensuring seamless functionality.

- Streamlined user interface: Simplifies navigation to reduce errors and save time.

Pros

- Fully customizable database architecture

- Centralized tracking for tasks and inventory

- Scalable design for growing manufacturing operations

- Intuitive interface for non-technical users

Cons

- Limited offline functionality for remote settings

- Lacks advanced analytics for complex manufacturing needs

Best for

Kohezion is a perfect match for small-scale Malaysian manufacturers, custom product designers, and niche market players. It caters to businesses that are struggling with the complex and difficult process of handling customized BOMs. Industries such as precision tooling, boutique, and specialty crafts will find Kohezion a suitable solution to streamline their operations saying No with complex systems.

Oracle

Oracle redefines how BOM management software can address the complexity and breadth of manufacturing landscapes. Its Agile Product Lifecycle Management connects product innovation with lifecycle analytics, ensuring seamless visibility from inception to retirement.

Built to scale operations and ensure precision in every detail, Oracle enables Malaysian manufacturers to streamline operations, accelerate product launches and deliveries, and maintain consistent quality standards. It is the epitome of reliability and sophistication.

Key features

- Complete product lifecycle oversight: Covers every stage, from concept to product retirement.

- Advanced change management tools: Facilitates precise data handling and lifecycle transitions.

- Collaborative ecosystem: Unites internal teams, suppliers, and external partners seamlessly.

- Comprehensive compliance management: Adheres to diverse industry regulations with precision.

- Data-driven decision framework: Powers actionable insights with detailed analytics and search tools.

Pros

- Industry-leading lifecycle management functionality

- Scalable architecture for enterprise-grade requirements

- Tailored configurations for diverse organizational roles

- Exceptional data security protocols

- Extensive integration across Oracle’s ecosystem

Cons

- Resource-intensive implementation process

- Complexity that necessitates advanced user training

Best for

Oracle is ideal for large-scale Malaysian and global enterprises in the high-tech, automotive, and aerospace sectors. Oracle fully supports and caters to manufacturers managing complex supply chains and multi-tiered product hierarchies. It is an extremely affordable solution if you are looking for a single, centralized platform to manage your product lifecycle.

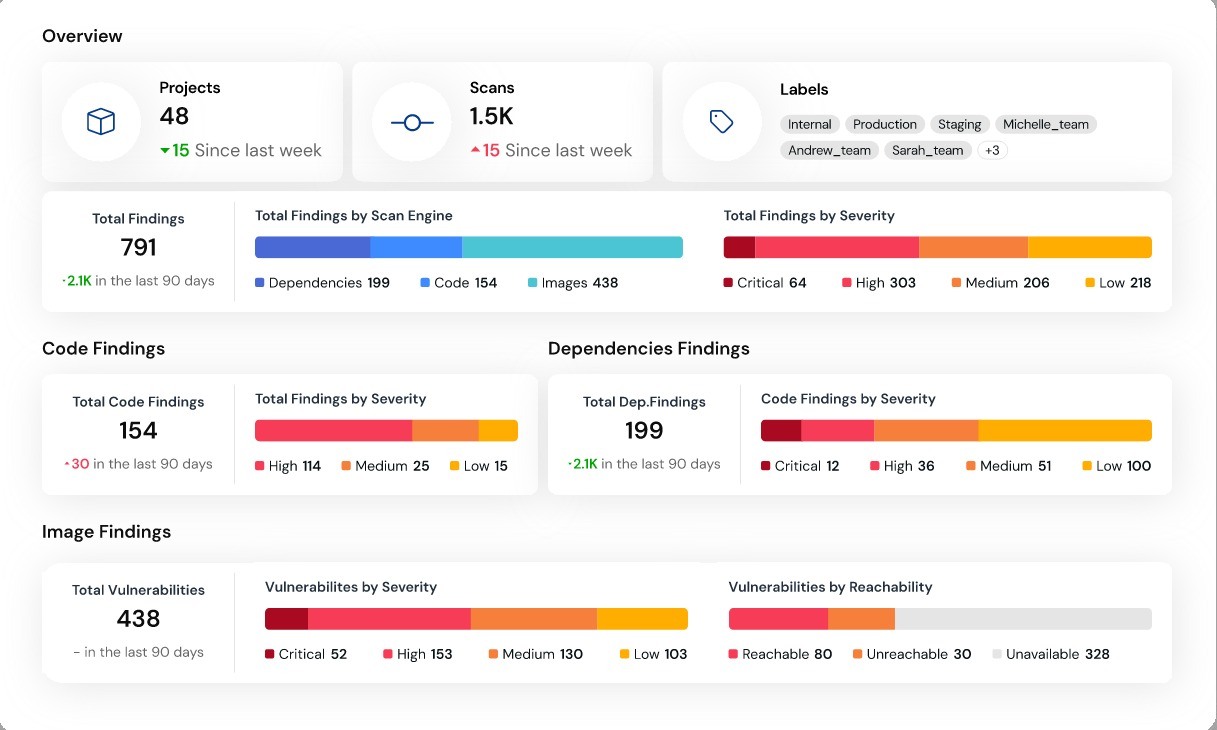

Mend.io

Mend.io transforms BOM management with advanced automation and industry-leading accuracy. It simplifies the entire process of managing open source and custom components, reducing risk and optimizing workflows.

Claiming high-speed performance with clarity and consistency at every step, Mend.io is the solution for Malaysian manufacturers to own a robust framework for tracking dependencies and securing applications.

With a focus on real-time updates, Mend.io as one of BOM management tools minimizes vulnerabilities while maximizing operational efficiency - which is crucial for the manufacturing process.

Key features

- Open-source library tracking: Monitors every open-source component with absolute accuracy and depth.

- Dependency documentation: Tracks direct and transitive dependencies for full supply chain transparency.

- Automated updates: Ensures seamless adjustments whenever components change or evolve.

- Security optimization: Identifies and mitigates risks across all BOM structures with advanced analytics.

- Comprehensive reporting: Generates in-depth insights for better decision-making and process refinement.

Pros

- Advanced dependency tracking tools

- Intelligent real-time update mechanisms

- Highly secure framework for open-source components

- Intuitive interface with powerful analytics

- Scalable solutions for growing enterprises

Cons

- Limited offline functionality

- Higher initial setup costs for small businesses

Best for

Mend.io suits mid-sized and large manufacturing enterprises with heavy reliance on open-source tools. It is extremely perfect for sectors including pharmaceuticals, consumer electronics, and medical device manufacturing. To balance rapid innovation with strict compliance standards, you will find this BOM management software one of the best choices.

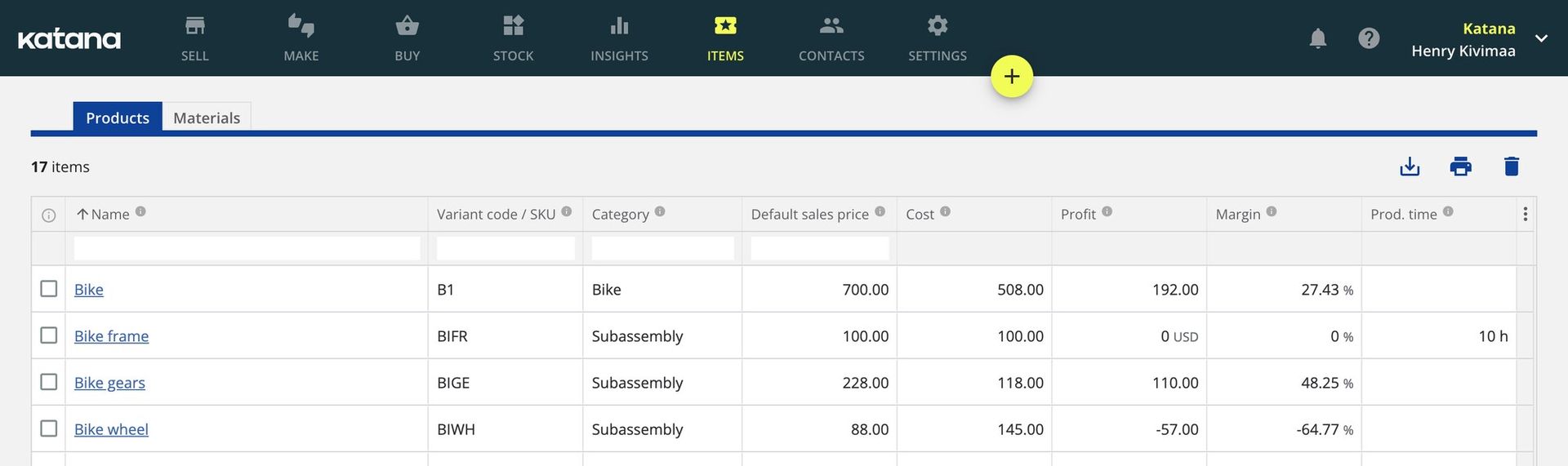

Katana

Katana transforms the way Malaysian small and medium-sized manufacturers manage their manufacturing processes with clarity and control. It bridges the gap between simplicity and sophistication as a BOM management software that radically enhances operational efficiency alongside accuracy.

Every feature of Katana is designed to harmonize production, inventory, and materials. Its real-time updates and intuitive interface redefine operational efficiency, aligning perfectly with modern manufacturing demands.

Key features

- Visual production dashboard: A streamlined view delivers comprehensive insights into every stage of production.

- Real-time inventory control: Accurate material tracking ensures seamless stock optimization at all times.

- Automated material allocation: Intelligent resource assignment prioritizes efficiency and minimizes delays.

- Task-level floor management: Detailed monitoring enhances shop floor transparency and operational precision.

- Integrated BOM management: Dynamic BOMs adapt to production needs, eliminating manual calculations.

Pros

- Intuitive real-time tracking tools

- Seamless material and workflow alignment

- Scalable features for evolving business needs

- Effortless navigation for faster adoption

- Practical tools for lean manufacturing operations

Cons

- Lacks advanced customization for niche industries

- Unsuitable for large-scale, complex manufacturing systems

Best for

Katana is the perfect fit for small to mid-sized manufacturers in craft production, niche electronics, and bespoke goods. It is beneficial for businesses that manage high-frequency, medium-volume manufacturing cycles with real-time resource needs. Businesses that directly impact consumers and prioritize agility, flexibility, and transparency will see this BOM management software as a potential investment.

Infor

As an outstanding BOM management software in Malaysia, Infor delivers a cutting-edge serie of features for industries with complex manufacturing needs. The system integrates seamlessly into existing business workflows, promoting accuracy and flexibility in multi-level BOM handling.

With global operations and deep customization, it addresses complex manufacturing situations. Its data-driven design also makes it easy for manufacturers to streamline processes and gain cost transparency.

Key features

- Multi-site BOM management: Centralized control simplifies global production and supply chain coordination.

- Lifecycle tracking for components: Comprehensive tools map every material's journey from procurement to completion.

- Advanced routing optimization: Dynamic path selection boosts production speed and resource efficiency.

- Cost analysis and revision tracking: Integrated features ensure historical changes and costs are fully documented.

- Industry-specific BOM configuration: Customizable setups address the unique needs of aerospace, automotive, and electronics.

Pros

- Extensive multi-location management tools

- Detailed lifecycle monitoring capabilities

- Dynamic routing for efficient workflows

- Deeply configurable BOM structures

- Compliance-focused documentation features

Cons

- Initial implementation complexity

- Higher learning curve for less experienced teams

Best for

Infor BOM management software is ideal for large-scale manufacturers handling multi-tiered production environments. High-tech equipment manufacturing, international supply chain management with diverse legal frameworks and advanced contractor networks in Malaysia will be the biggest beneficiaries.

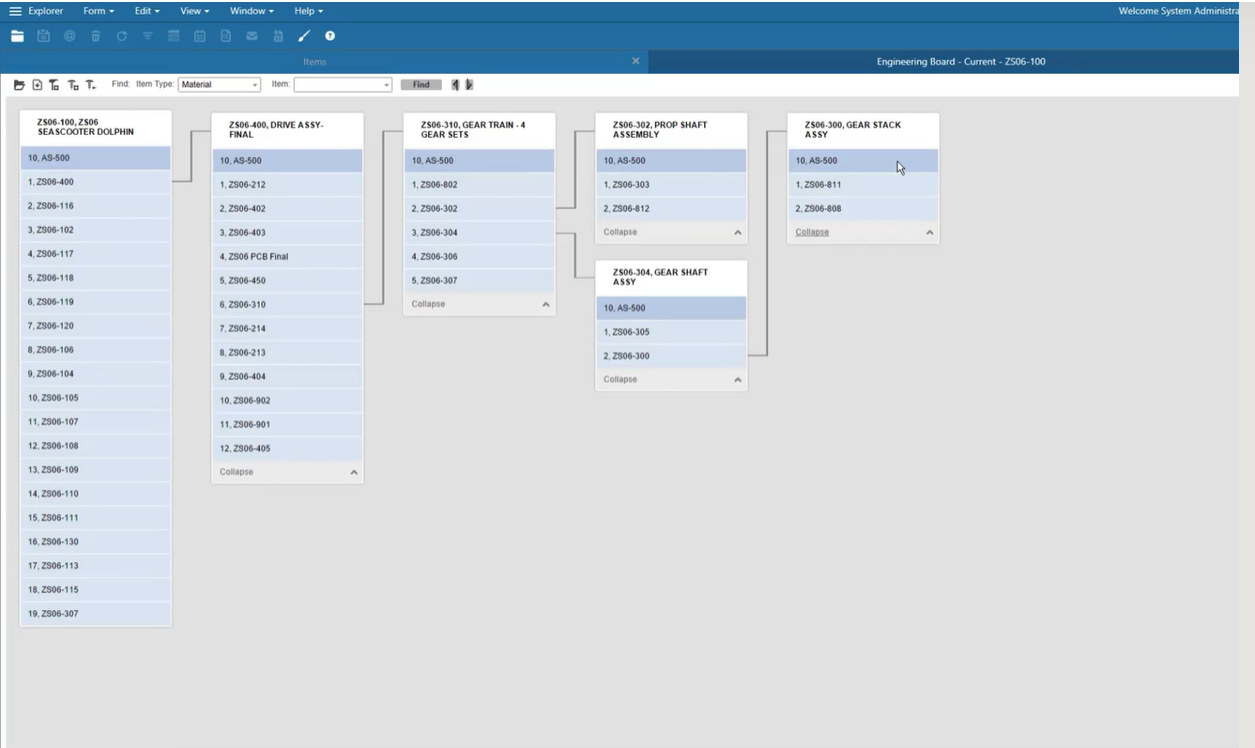

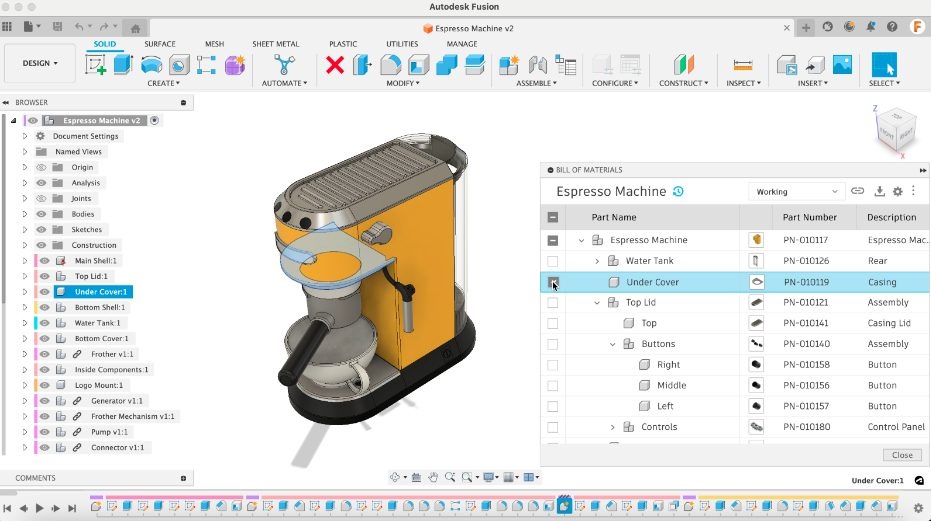

Autodesk Fusion 360

Autodesk Fusion 360 brings a variety of BOM management features with cloud-based PLM tools and seamless CAD integration. It connects design and manufacturing processes for manufacturing sectors based on precision and collaboration. The centralized platform of this BOM management software connects product data, lifecycle management, and real-time collaboration.

It improves efficiency in managing complex projects and dynamic engineering changes.

Key features

- Integrated CAD-BOM synchronization: Directly links BOM data with design files for seamless updates and traceability.

- Pre-configured change workflows: Simplifies change order processes with automated and structured workflows.

- Cloud-based PLM platform: Centralizes product lifecycle data, ensuring cross-team accessibility.

- Advanced KPI dashboards: Tracks performance metrics with clear, customizable visual reports.

- API and ERP integration: Facilitates data flow between PLM, ERP, and CRM systems for operational efficiency.

Pros

- Seamless CAD and BOM integration

- Pre-configured workflows for quick deployment

- Centralized data access for distributed teams

- Real-time performance monitoring through dashboards

- APIs for flexible system connectivity

Cons

- Extended time required for initial setup

- Complex interface for new users

- Dependency on stable cloud access

Best for

Autodesk Fusion 360 is designed specifically for mid-tier manufacturers and design-centric enterprises that handle complex prototyping and high-variability production. Specific industries that will find this BOM management tool perfect include consumer electronics, medical devices, or cross-disciplinary teams based in multiple domestic and international locations.

CycloneDX

CycloneDX is BOM management software for businesses looking for a comprehensive solution and wanting to minimize risks in the supply chain. It provides a powerful framework for managing BOMs across software, hardware, and operational workflows. Its dedicated focus on cybersecurity is unique in the overall BOM management landscape in Malaysia.

CycloneDX also seamlessly integrates into compliance monitoring and vulnerability detection processes for timely remediation.

Key features

- Software Bill of Materials (SBOM): Tracks dependencies and components in software projects with high precision.

- Hardware Bill of Materials (HBOM): Offers granular insights into hardware components and their lifecycle.

- SaaS BOM management: Ensures complete oversight of SaaS-based dependencies and subscriptions.

- Operations Bill of Materials (OBOM): Captures operational elements critical to production and maintenance.

- Vulnerability Disclosure Reports (VDR): Centralizes vulnerability reports for proactive risk management.

- Vulnerability Exploitability Exchange (VEX): Identifies and classifies exploitable vulnerabilities in real-time.

Pros

- Advanced cybersecurity capabilities integrated with BOM management.

- Seamless handling of complex multi-layered BOM structures.

- Detailed vulnerability tracking for software and hardware ecosystems.

- Strong compliance support aligned with industry and regulatory standards.

- Scalable for large enterprises with diverse supply chains.

Cons

- Steep learning curve for teams unfamiliar with cybersecurity frameworks.

- Limited user interface customization options.

Best for

CycloneDX is ideal for enterprises prioritizing cybersecurity in sectors like critical infrastructure, defense manufacturing, and technology hardware. Large-scale organizations with global supply chains and high compliance needs will benefit most.

Important Criteria to Choose The Best-suited BOM Management Software

Choosing the right BOM management software is crucial to the efficiency and accuracy of your manufacturing process. A wrong move at this early stage can disrupt your processes and increase your business costs, instead of delivering the valuable benefits as expected.

The criteria you must understand and take a deep look at are listed below and will be a useful guide for you before making an important decision.

Scalability for growing operations

The BOM management software must support the increasing complexity of products and expanding manufacturing needs. It should accommodate large data sets and multi-level BOMs without performance lags. Scalability protects the short-term and long-term operational goals of the business, suitable for future growth.

Seamless integration capabilities

The solution should have the ability to deeply integrate with the enterprise's existing ERP, PLM, and supply chain systems. The seamless flow of data between platforms eliminates fragmentation and enhances collaboration. Integration drives streamlined processes across departments and external partners.

Advanced data accuracy features

Precise tracking of components, revisions, and dependencies must be a core function. Automatic updates and error detection prevent miscalculations, which can lead to costly errors.

Having accurate data tables minimizes risk and ensures consistent output quality.

Robust security frameworks

The platform must include features that guard against data breaches and cyber risks. Compliance with global security standards ensures protection across supply chains. Strong encryption and user permissions safeguard sensitive information.

User-friendly interface with minimal training needs

The system should deliver intuitive navigation and clear workflows. A steep learning curve can slow adoption and frustrate teams. To address this, a certain level of simplicity is key to maximizing productivity early in the adoption phase, accelerating process maturity without impacting ongoing manufacturing stages.

Definition and Common Features of BOM Management Software

Precision in manufacturing begins with the right BOM management.

BOM management software organizes and controls the components, processes, and documentation needed for manufacturing. It tracks the relationships between assemblies, subassemblies, and parts. Manufacturers rely on it to maintain data accuracy, streamline workflows, and prevent costly errors. A robust solution safeguards against inefficiencies and strengthens the manufacturing ecosystem.

Some common key features when using BOM management software that may surprise you:

- Version control: Tracks revisions and changes made to the BOM, maintaining a clear history of updates and preventing errors due to outdated information.

- Centralized data storage: A single repository for all BOM data, ensuring accuracy, consistency, and easy access across departments.

- Integration with other systems: Seamlessly connects with ERP, inventory, and procurement software for improved data flow and real-time synchronization.

- Customizable templates: Allows users to create BOMs tailored to specific product types or industry standards.

- Collaboration tools: Provides features for teams to communicate and share data easily. They improve coordination between design, engineering, and production departments.

Final Thoughts

In conclusion, adopting the right BOM management software is pivotal for refining production processes and driving supply chain excellence. A tailored solution can streamline workflows, minimize errors, and integrate seamlessly with enterprise systems. Top 10 BOM management software that we’ve sent you in this article will ease your selection process among countless systems in the Malaysian market.

By selecting the best-fit tool, businesses can gain critical insights, enhance cost control, and future-proof their manufacturing capabilities.

Don't hesitate to contact A1 Consulting if you want custom consultation or any advice about implementing Odoo ERP for manufacturing for SMEs businesses in Malaysia.