Calvin Kuan

A1 Consulting Country Head

Calvin Kuan serves as Country Head of A1 Consulting Sdn Bhd, where he leads the overall vision and operations for delivering customized ERP solutions across Malaysia, working with clients in all regions of the country. Calvin has years of management consulting and implementation experience with ERP. His leadership blends strategic insight with hands-on expertise, ensuring every project delivers measurable value for clients.

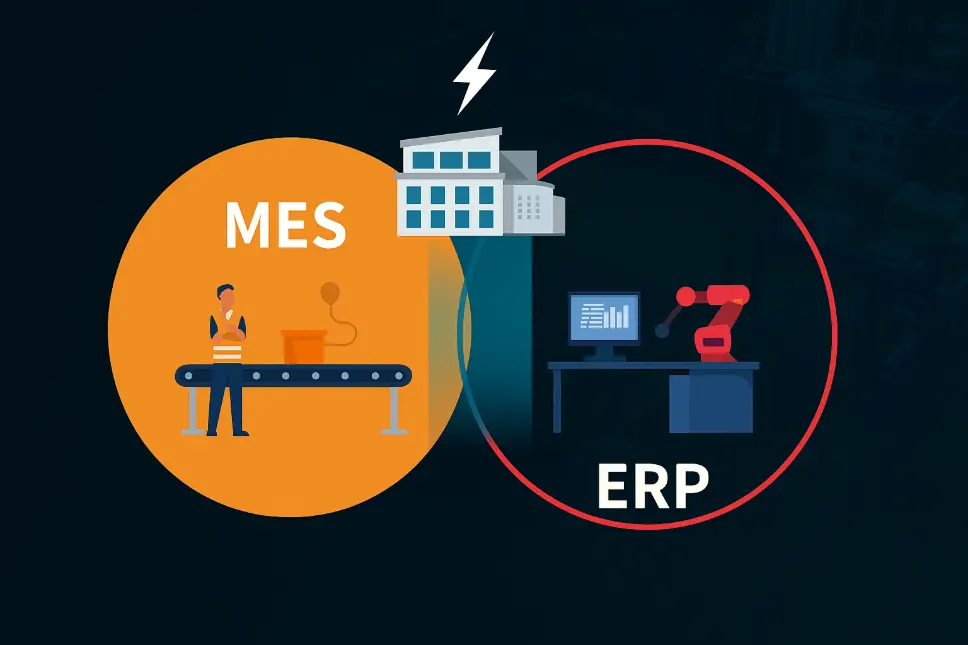

After two decades of working with manufacturers across Asia and helping them implement digital transformation, one of the most shared pain points businesses experience is simply answering the question: "Do I need MES, ERP, or both?" This is often not a black-and-white answer; however, recognizing the separate roles that each of these systems can play in a business can mean the difference between being at risk of being insignificant, and having a competitive advantage.

The Manufacturing Revolution is Here

Over my 20 years working with manufacturers across Malaysia, Singapore, and throughout Asia just in general, I have seen a tremendous change take place. Where this was once a digital upgrade that seemed like a "nice-to-have," it has since transitioned into a must-have for survival! Those businesses that are adopting Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems are not only becoming more efficient; they are totally transforming the way they conduct business.

I would like to share what I have learned through understanding the similarities and differences between these two powerful systems and why the shrewdest manufacturers are implementing both.

MES: Your Production Floor Command Center

Think of MES as the nerve center of your production floor. It's the system that lives and breathes with your manufacturing operations, capturing every machine cycle, every quality check, and every production milestone in real-time.

When I work with clients implementing an MES, I always reinforce its primary mission: bridging the gap between planning and execution. Your ERP may indicate what needs to be produced, but MES facilitates its efficient and timely execution to specification.

What MES delivers

- Real-time production visibility - You know exactly what is happening on your floor, right now.

- Dynamic work order management - You can adapt to changes with no disruption to the current production schedule.

- Quality control integration - Catch issues before they become costly problems

- Performance tracking - Understand the efficiency of machine and operator speeds.

- Production scheduling - Balance workloads and minimize downtime

ERP: Your Business Intelligence Backbone

ERP operates on a completely different level. While MES is concerned with the "how" of manufacturing, ERP is concerned with the "what, when, and why" occurring in the organization as a whole. It's your strategic command center, connecting manufacturing with finance, procurement, sales, and beyond.

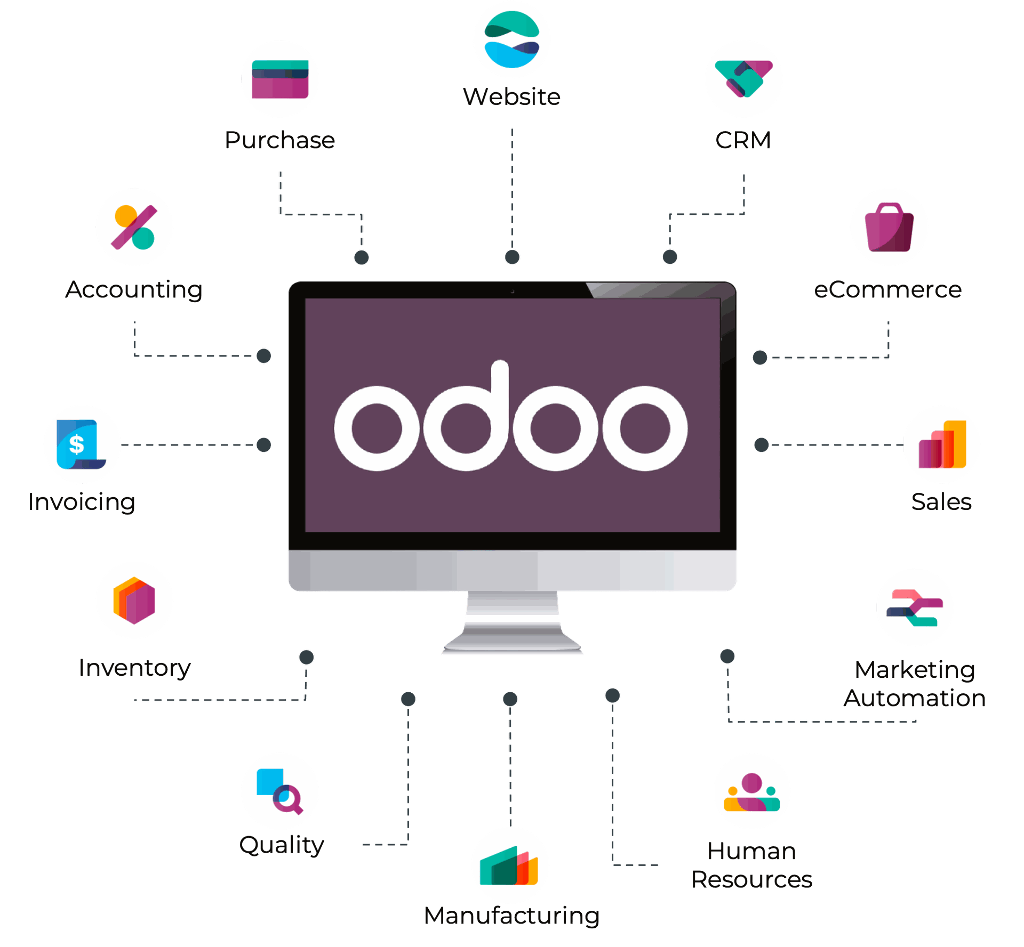

In my experience, the companies who think of ERP systems as an accounting system miss out on 80% of their potential. Modern ERP - especially flexible platforms like Odoo - can transform how you plan, execute, and optimize your entire business operation.

ERP's Strategic Functions:

- Integrated financial management - Real-time profitability and cost analysis

- Intelligent inventory control - Optimize stock levels and reduce carrying costs

- End-to-end order processing - From quote to cash, seamlessly

- Supply chain optimization - Coordinate with suppliers and logistics partners

- Resource planning - Align capacity with demand across all departments

The Critical Differences between MES and ERP

Aspect | MES | ERP |

Primary Mission | Real-time production control and optimization | Organization-wide planning and resource management |

Data Focus | Live operational data from machines and workers | Aggregated business transactions and analytics |

User Base | Production managers, operators, quality teams | Executives, finance, procurement, sales teams |

Integration Points | Factory equipment, IoT sensors, production tools | Business applications across all departments |

Decision Timeframe | Immediate tactical decisions | Strategic planning and long-term optimization |

Success Metrics | OEE, cycle time, quality rates, throughput | ROI, profit margins, inventory turns, cash flow |

MES vs ERP - Why You Need Both?

Here is what I'd tell every customer I meet: MES and ERP are not enemies, they are friends on the way to transformation. Each performs good for provided purposes individually, together they are exponentially better.

When to Start with MES

When the problems you face are on the production floor, i.e. manual data collection, quality challenges, no real-time visibility, the MES implementation makes an immediate difference. I have seen manufacturers achieve as much as 30% reduction in waste and 40% improvement on-time delivery within months of implementation.

When to Start with ERP

Whenever your pain points involve inventory management, limited visibility into financials, or cross department communication, the ERP is foundational to scaling the growth. It's even more critical for manufacturers planning on growth or facing complex regulatory requirements.

What you gain from integration

When MES and ERP work together, you get:

- Unified data flow - Real-time production data automatically updates business systems

- Predictive planning - ERP forecasts demand while MES optimizes execution

- Complete traceability - Track products from raw material to customer delivery

- Agile response - Quickly adapt to market changes with synchronized planning and execution

Odoo ERP: The Perfect Integration Partner

I have had experience implementing many ERP systems in my career, and I find that Odoo has both flexibility and integration capabilities. Its modular architecture means that manufacturers can begin with their core functions and expand over time, which is ideally suited for the Asian market where business grows rapidly.

And here is Why Odoo Works For Manufacturing

- Modular scalability - Add capabilities as your business grows

- Open architecture - Integrates with other systems seamlessly, including MES

- Manufacturing-specific features - Including work orders, quality control, maintenance management

- Cost-effective - Lower total cost of ownership compared to traditional ERP

- Local support - Strong ecosystem in Malaysia and across Asia

> Read more: Boost Manufacturing Efficiency with Odoo MES: Meaning & Key Benefits

Making Integration Work: My Proven Approach

From hundreds of implementations, this is my framework for successful MES-ERP integrations:

Phase 1: Strategic Assessment

- Map current processes and identify pain points

- Define specific goals for both systems

- Assess data flow requirements between shop floor and business systems

Phase 2: System Configuration

- Configure Odoo ERP modules (Manufacturing, Inventory, Accounting, Quality)

- Set up MES with production-specific workflows

- Design integration points for seamless data exchange

Phase 3: Integration Implementation

- Develop APIs and middleware for real-time data synchronization

- Create custom modules where needed

- Test thoroughly with real production scenarios

Phase 4: Change Management

- Train teams on integrated workflows

- Develop standard operating procedures

- Create support structures for ongoing optimization

Real-World Success Story

To share a recent example from Penang- one of our customers is a precision manufacturer using Odoo ERP and the MES module - it had challenges coping with inventory accuracy and production visibility. After we implemented Odoo ERP along with MES the client experienced:

- Inventory accuracy improved from 75% to 98%

- Production visibility increased from daily to real-time

- Order fulfillment time reduced by 35%

- Quality incidents decreased by 50%

- Overall equipment effectiveness (OEE) improved by 25%

The integration allowed them to respond to customer changes within hours instead of days, significantly improving customer satisfaction and competitive position.

Your Digital Transformation Journey Starts Now

The question is not about whether you need an MES or ERP - but how fast can both systems be implemented to work together. Manufacturing in Asia is becoming increasingly competitive, and the companies that will thrive are those that embrace integrated digital solutions.

At A1 Consulting, we don't just implement systems - we help transform businesses. Our program is designed to leverage our technical capabilities with our real business experience for a successful integration of your MES and ERP applications that produces results - and not just new software.

Are You Ready to Change Your Manufacturing Operations?

Digital transformation is not a destination, it's a journey. Whether you take your first step with MES, ERP, or both, it's critical to make that first step with a partner that can help.

Get in touch with A1 Consulting today so we can show you how MES and Odoo ERP for Manufacturing integration improves manufacturing operations. With our proven methodology, and experience in an Asian manufacturing context, we will help you build the digital foundation for your ongoing sustainable growth and competitive advantage.

Frequently Asked Questions

Q: Can MES and ERP operate as standalone systems?

A: Absolutely. Each system delivers value on its own. However, integration multiplies their impact by creating seamless data flow between production and business operations.

Q: What is the typical ROI for MES-ERP integration?

A: From our experience with clients, most manufacturers are able to achieve ROI in 12-18 months through gains in efficiency, waste reduction, and better decision-making.

Q: Is Odoo suitable for small manufacturers?

A: Yes. Odoo's modular approach make it ideal for SMEs as it allows you to start with the basic modules and only expand as your business grows.

Q: How long does integration typically take?

A:Integration duration will vary based on the extent of integration complexity, but with proper and timely planning and support most projects will take 6-12 months.

Q: What ongoing support is needed?

A: Successful integration requires ongoing optimization, user training, and system updates. We provide comprehensive support to ensure long-term success.