ERP & Odoo ERP: key feature for Malaysian Manufacturers

According to Statista, Malaysia’s manufacturing sector remains a cornerstone of the national economy and a key driver of export competitiveness. Manufacturing value added is projected to reach around USD 130.4 billion in 2025, growing at a CAGR of approximately 2.4% between 2025 and 2029, underlining its continued strategic importance.

From January to May 2025, Malaysia’s manufacturing sector recorded approximately RM794.7 billion in sales value, a 3.8% year-on-year increase, while employing around 2.40 million people. Wage growth of 1.9% during the same period further highlights rising cost pressures on manufacturers.

A defining feature of Malaysian manufacturing is its export orientation. Export-oriented industries contribute about 71.1% of total manufacturing sales, placing strong demands on efficiency, delivery reliability, traceability, and compliance with international standards. In this environment, manual processes and disconnected systems quickly become a competitive disadvantage, reported by BusinessToday.

This is where Odoo ERP becomes highly relevant. Odoo is a flexible, modular ERP platform that supports end-to-end manufacturing operations, from planning and production to finance and quality, while remaining scalable for both SME manufacturers and multi-plant industrial groups. With localisation delivered by Odoo partners in Malaysia, it aligns well with local regulatory, accounting, and operational realities.

Key Challenges in Malaysia’s Manufacturing Industry

Fragmented Systems and Manual Processes

Many Malaysian factories still rely on separate spreadsheets or siloed software for production planning, inventory, purchasing, and finance. This fragmentation makes it difficult to obtain real-time visibility, calculate accurate product costs, or respond quickly to changes in demand or supply disruptions.

Export Pressure and Compliance Requirements

With more than 70% of manufacturing sales linked to exports, Malaysian manufacturers face increasing pressure from global buyers to meet strict quality, traceability, and delivery KPIs. Manual tracking and disconnected systems raise the risk of non-compliance, delayed shipments, and customer penalties.

Workforce and Productivity Constraints

Manufacturing employment growth has been relatively modest while output expectations continue to rise. Instead of expanding headcount, manufacturers are turning to digital tools to increase sales value per employee and overall productivity.

Industry 4.0 Readiness Gap

Across ASEAN, only about 13% of companies have meaningfully started their Industry 4.0 journey. Malaysian manufacturers who delay ERP-driven digital transformation risk falling behind regional competitors that are already investing in connected planning, smart production, and data-driven decision-making.

Why Odoo ERP for Manufacturing in Malaysia?

Core Odoo Manufacturing Capabilities

Odoo provides an integrated suite of modules designed for manufacturing operations, including:

- Manufacturing (MRP) - manage work orders, routings, and production scheduling

- Inventory - real-time stock visibility, lot/serial tracking, and reordering rules

- Purchase - supplier management and automated replenishment

- Quality - quality control points, inspections, and non-conformance tracking

- Maintenance - preventive and corrective maintenance for production assets

- PLM - manage engineering changes and BOM revisions

- Accounting & Finance - real-time costing and financial control

- Sales & CRM - integrated order management and customer visibility

Key manufacturing-specific features include:

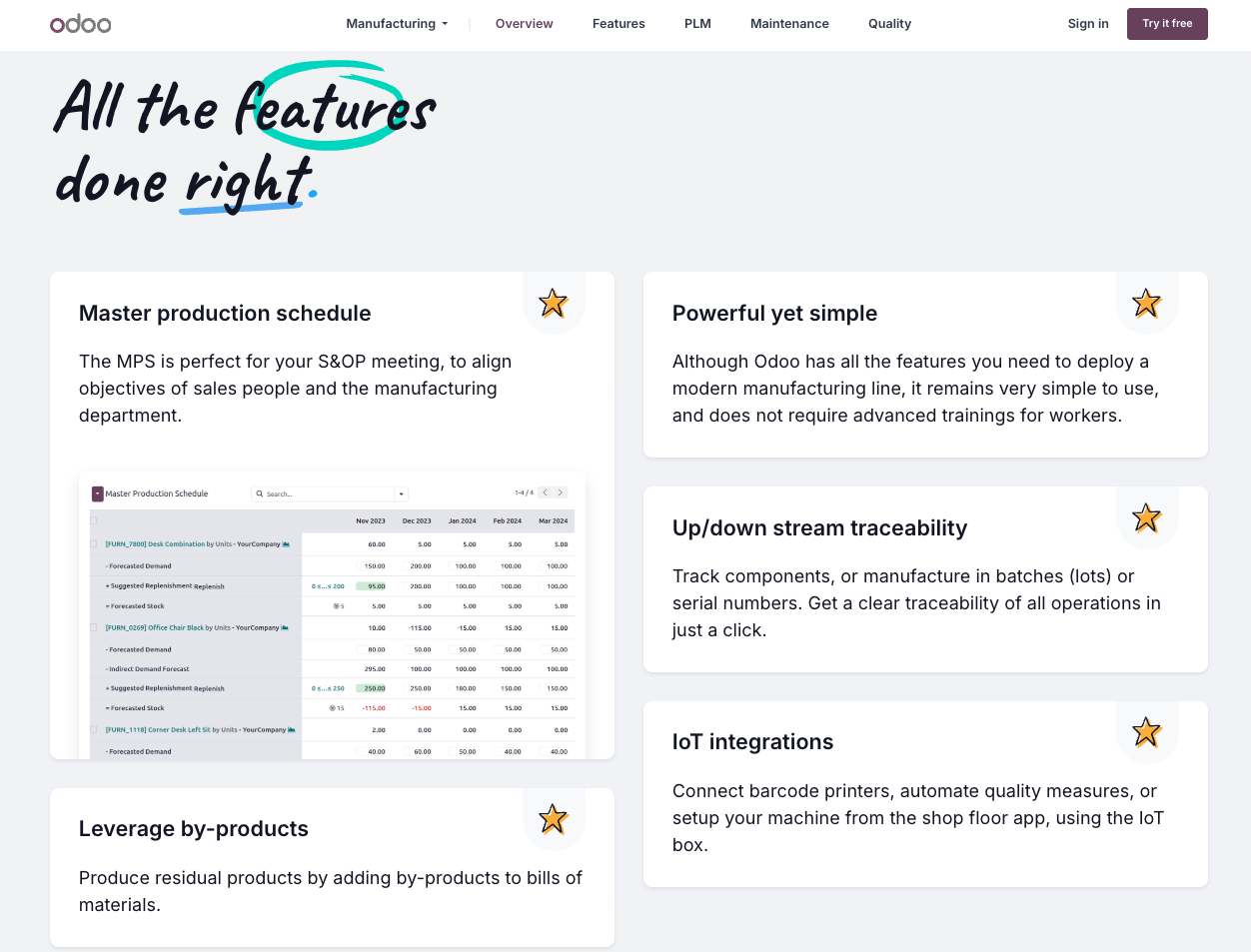

- Master Production Schedule (MPS) based on demand forecasts and stock levels

- Automatic Manufacturing Order creation triggered by sales orders

- Integrated quality checks embedded directly into production workflows

- End-to-end traceability from raw materials to finished goods

Fit for Malaysian Manufacturing Models

Odoo is well-suited for both export-and domestic-oriented manufacturers, including high-growth sectors such as food processing, metal fabrication, electronics, and precision engineering. These industries often manage complex BOMs, strict quality requirements, and variable demand, all of which Odoo handles natively.

Through certified Malaysian partners, Odoo can be localised for Malaysian accounting standards, tax reporting, payroll, and statutory compliance, with integration to local banks and third-party systems where required.

Odoo vs Traditional ERP for Manufacturers

Aspect | Odoo ERP | Traditional ERP (Legacy / On-Premise) |

Licensing model | Modular, subscription-based; easy to start small and scale | High upfront licence and maintenance costs |

Manufacturing features | Integrated MRP, inventory, quality, maintenance, PLM in one suite | Often split across separate modules or add-ons |

Localisation | Malaysian partners deliver COA, tax, payroll, local integrations | Localisation often costly and slower |

Flexibility | Open, customisable, strong ecosystem | More rigid, changes require expensive CRs |

Step-by-Step Odoo ERP Implementation for Malaysian Manufacturers

Step 1: Diagnose Current Situation and Set Business Objectives

Start with a structured diagnostic of existing systems including Excel files, legacy software, and manual workflows, across production, inventory, purchasing, finance, and quality.

Define 3–5 measurable business objectives, such as:

- Reduce production lead time by 10–15%

- Improve Overall Equipment Effectiveness (OEE)

- Reduce stockouts and excess inventory

- Increase sales value per employee

Step 2: Design the Future-State Manufacturing Process

Map end-to-end processes including order-to-cash, procure-to-pay, plan-to-produce, and quality loops.

Define the required level of detail for BOMs, routings, work centres, and quality checkpoints, aligned with Industry 4.0 ambitions promoted by MIDA and national strategies.

Step 3: Select Odoo Modules and Architecture

Core modules for most factories include:

- Manufacturing, Inventory, Purchase

- Quality, Maintenance

- Accounting, Sales, CRM

Optional modules:

- PLM for engineering change management

- Project for NPI and tooling projects

- HR for workforce planning

Choose the deployment model, cloud, hybrid, or on-premise, based on data sensitivity, connectivity, and scalability needs. Hybrid models are increasingly popular among Malaysian manufacturers.

Step 4: Data Preparation and Migration

Clean and standardise:

- Item masters and BOMs

- Routings and work centres

- Vendors, customers, and price lists

- Opening balances and inventory

Accurate BOMs and consistent units of measure are critical, as they directly affect costing accuracy and MRP performance in Odoo.

Step 5: Configure, Integrate, and Localise for Malaysia

Configure:

- Production calendars and work centre

- Scrap rules and quality control points

- MPS and replenishment parameters

Integrate Odoo with:

- MES or shop-floor data collection systems

- Scales, barcode scanners, or PLCs where applicable

Apply Malaysian localisation for tax, statutory reporting, and payroll through certified Odoo partners.

Step 6: Pilot Implementation and UAT

Begin with a pilot scope - one product family, production line, or plant.

Conduct full User Acceptance Testing (UAT) with planners, supervisors, quality engineers, storekeepers, and finance teams using real production scenarios before go-live.

Step 7: Training, Change Management, and Go-Live

Provide role-based training for:

- C-level and plant management

- Supervisors and planners

- Operators and back-office users

Align dashboards and KPIs so leaders can track improvements in efficiency, asset utilisation, and defect rates, reflecting typical digital transformation gains such as:

- 15–20% improvement in asset efficiency

- 20% defect reduction

Step 8: Continuous Improvement and Industry 4.0 Roadmap

Post-stabilisation, extend capabilities with:

- Advanced production scheduling

- IoT sensor integration

- AI-driven demand forecasting

- Deeper MES–ERP synchronisation

Benchmark performance against national productivity targets and Industry 4.0 standards to remain competitive regionally.

>>> Learn more about the all-in-one Odoo ERP for Manufacturing industry implementation.

Business Benefits: What Malaysian Manufacturers Can Expect from Odoo Implementation

Productivity and Cost Efficiency

Well-executed digital transformation initiatives in manufacturing have shown:

- 25–40% workforce reduction

- 15–20% asset efficiency improvement

- 10% shorter production lead time

- 20% fewer defects

Odoo’s integrated reporting enables data-driven decisions on material usage, costing, and OEE to support these outcomes.

Visibility, Traceability, and Compliance

Real-time integration across sales, production, inventory, and quality provides full traceability - a critical requirement for export-oriented Malaysian manufacturers serving global customers.

Scalability for Growth and Investment

ERP platforms like Odoo provide the scalable digital backbone needed to support new plants, higher volumes, and more complex operations.

How to Choose the Right Odoo Implementation Partner in Malaysia

When selecting an Odoo partner, Malaysian manufacturers should prioritise:

- Proven manufacturing references (metals, food processing, electronics)

- Clear Industry 4.0 understanding and shop-floor experience

- Structured implementation methodology

- Local team presence and post-go-live support

- Strong experience in Malaysian localisation, MES integration, and compliance

A1 Consulting - Gold Odoo Partner in Malaysia, combines Odoo expertise, manufacturing process knowledge, and Malaysia-specific localisation, making us well-positioned to support successful ERP transformation.

>>> Discover Top 5 Odoo ERP partners in Malaysia in 2026

Conclusion

If your factory is still managing operations across spreadsheets and disconnected systems, now is the time to act.

Request an ERP readiness assessment to evaluate your current state and define a phased Odoo implementation roadmap - from a pilot line to full multi-plant rollout. Don’t hesitate to contact us or discover our information hub for ERP knowledge!

Sally N.

BDM - Partner and Alliance

With over 7 years of experience in ERP advisory, Sally has worked closely with SMEs across Malaysia to streamline operations and drive digital transformation. Her deep understanding of business processes and hands-on approach have made her a trusted advisor to many growing companies. Through this blog post, Sally aims to share practical insights and real-world lessons drawn from her implementation experience, offering guidance to businesses navigating their own ERP journey.